Nanometric 3D shape measurement for any reflective optic, from lab to shop floor

Our patented coaxial deflectometry delivers interferometer‑grade accuracy without reference surfaces or complex setups, even on freeforms and molds that CMMs and interferometers struggle to measure.

Easy to operate

Table‑top system, vibration‑insensitive, no reference optics or complex alignments required.

Lower total cost

Interferometer‑level performance with significantly lower investment and operating costs than high‑end interferometers and CMMs.

One system, many shapes

From flats and spheres to complex freeforms, molds, and microlens arrays, with the same setup.

Challenges in precision optics manufacturing

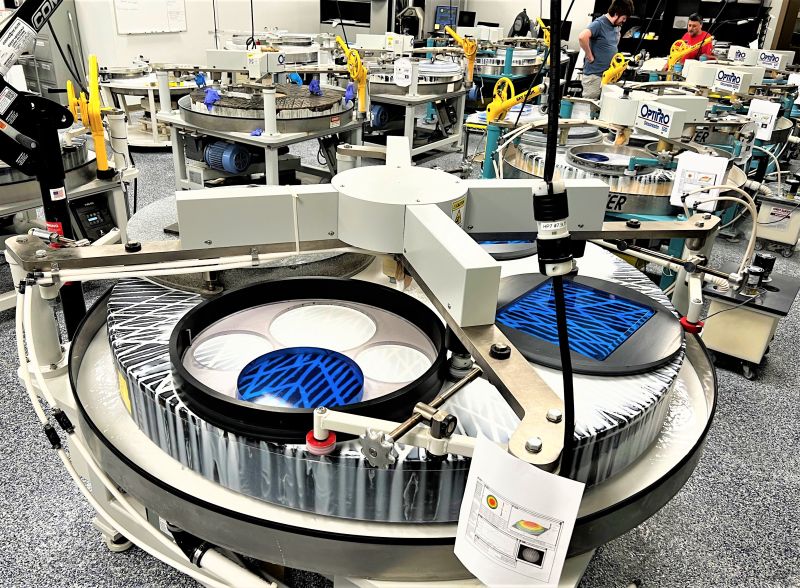

Metrology is often the bottleneck, not the polishing.

Complex setups, fragile reference optics, and long alignment times make interferometric measurements slow and hard to scale in production.

Many critical optics are hard or impossible to measure.

Freeforms, molds, strongly aspheric or off‑axis parts often require custom CGHs, complex stitching, or end up being sampled too rarely.

High‑end instruments are expensive and under‑used.

Interferometers and CMMs represent a large investment, but they are often reserved for experts and final inspection instead of being used throughout the process.

Measurement times slow down your throughput.

Single measurements can take tens of minutes including setup, blocking polishing machines and delaying release to production.

Results depend heavily on metrology experts.

Interpreting fringes, setting up references, and validating results requires scarce expertise, making it difficult to scale quality control across shifts.

How RayMaster10 solves them

Remove the metrology bottleneck.

RayMaster10 provides fast, fully quantitative 3D shape measurements without reference optics or complex alignments, making high‑end metrology usable directly on the shop floor.

Measure optics that interferometers and CMMs struggle with.

Patented coaxial deflectometry enables absolute surface measurements on flats, spheres, aspheres, freeforms, molds and microlens arrays with a single, flexible setup.

Interferometer‑grade performance at lower total cost.

You get nanometric accuracy comparable to high‑end interferometers and CMMs, with a more compact system, simpler infrastructure requirements, and lower overall investment.

Shorten measurement and setup time.

Table‑top configuration, vibration‑insensitive design and no need for CGHs or custom fixtures significantly reduce setup time and per‑part measurement time.

Make advanced metrology accessible to more operators.

A robust measurement process, simplified setup, and clear 3D shape outputs reduce reliance on a few metrology experts and make it easier to deploy consistent quality control across shifts and sites.

For precision optics manufacturers

Typical parts we measure

- Flat, spheric, aspheric and freeform lenses (including high‑NA and off‑axis parts).

- TIR and imaging optics for space, laser, health, AR/VR and automotive applications.

- Flat, spheric, freeform and off‑axis mirrors, including large aperture mirrors up to several hundred millimeters.

- Precision molds and tooling for glass or plastic optics.

- Microlens arrays, structured surfaces and other complex reflective components like axicons, tores.

Size and performance

- Part diameters from small optics (around 10–15 mm) up to large mirrors (800 mm class).

- Reflective surfaces from highly polished mirrors to low‑reflectivity glass (down to a few percent reflectivity).

- Nanometric 3D shape accuracy suitable for demanding applications in imaging, laser, space and high‑end industrial optics.

- Better than 5 nm accuracy on mid and high spatial frequencies and around 15 nm on low frequencies, while remaining insensitive to vibrations and air turbulences.

- Single-shot acquisition in 10 seconds, with results available after only a few minutes of processing.

Experimental evidence

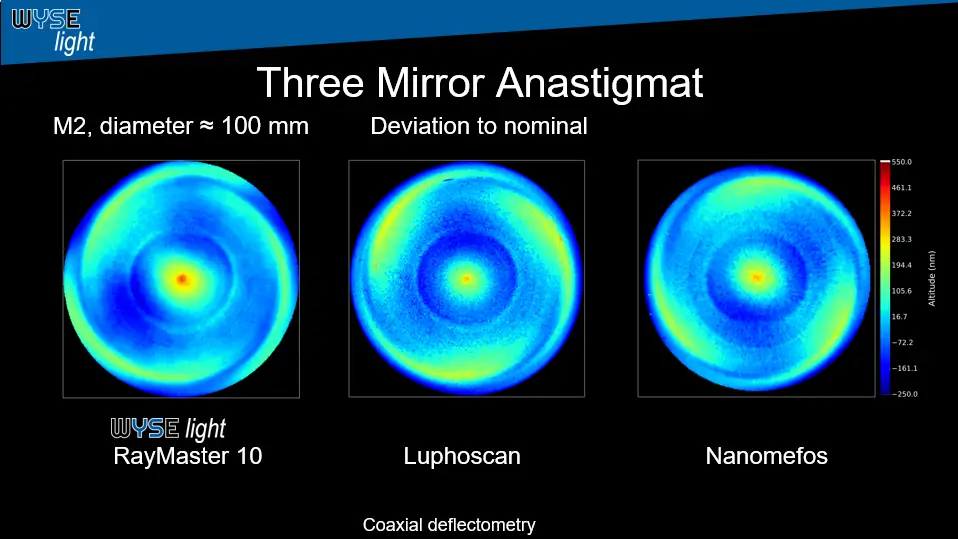

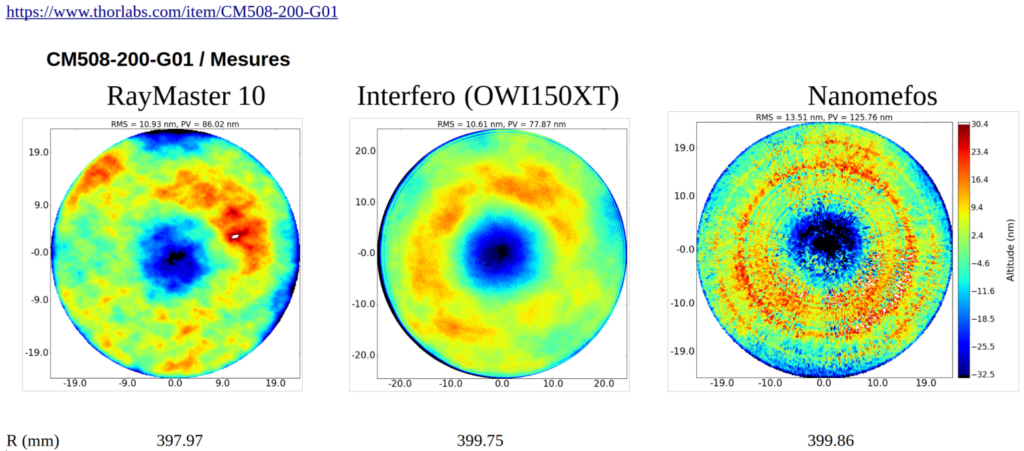

- In a comparative study with a manufacturer of precision optics equiped with 2 high-end interferometers and a Nanomefos CMM, RayMaster10 consistently delivered nanometric shape results closely matching a high‑end interferometer, without reference optics, while a Nanomefos CMM showed larger deviations and scan artefacts on several parts.

| Part type | RM -interfero | RM- NMF | Intefero – NMF |

| Flat | 13.7 | 28.2 | 32.4 |

| Sphere | 6.7 | 9.8 | 12.2 |

| Asphere | 15.6–27.1 | 25.5–42.5 | 20.1-29.6 |

Coaxial deflectometry: our patented technology

- Overcomes the fundamental shape ambiguity of classic deflectometry.

- Delivers absolute shape measurements without CGHs or dedicated reference surfaces.

- Tested against the best metrology instruments (Zygo interferometers, Luphoscan and Nanomefos CMM)

Nanometer accuracy with our easily deployable tabletop system

WYSE light RayMaster10 system is composed of a measurement unit, a display screen to illuminate the sample, an optical mount that fits samples from 1 to 6 » in diameter, a display monitor plus keyboard and mouse, and a few additional accessories used to make measurement easy for all. It can be used on a regular desk, deflectometry being basically insensitive to vibrations. We even make live measurements during trade shows on folding tables with a repetabilty of 2 nm RMS.

Let’s work together

Curious to see how RayMaster10 fits your parts and tolerances? We can demo on your optics, rent our systems, or run measurements for you.

Strategic supporters

We are a Luminate portfolio company. Wyse Light has been selected in March 2025 with 10 others startups among 197 candidates from all over the world to integrate the Nextcorps Luminate startups accelerator, the first and largest startups accelerator dedicated to the optics photonics sector.

Wyse Light is actively supported by the Saint-Etienne metropolitan area through its innovation support programs. Wyse Light is Mind-certified and housed in the building dedicated to the most innovative high-tech startups (bâtiment des hautes technologies).

EXIMIUM is an investment holding company with an entrepreneurial culture that acquire of both majority and minority stakes, while developing financial activities. With a consolidated workforce of 500 people, EXIMIUM manages more than €400 million in assets for its own account. EXIMIUM supports Wyse Light since 2023.

Wyse Light is supported by the French Public Bank of Investment though its financial support programs dedicated to the most innovative French deep tech startups.