From classic deflectometry…

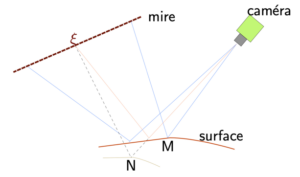

The principle of deflectometry is very simple: an observer who looks at a reflective surface sees the distorted reflection of the environment around it. The deformations are proportional to the shape of the reflective object. If we master the parameters of the reflected reference image, we can accurately deduce the shape of the reflective object.

Deflectometry is a non contact measurement technique. As such, it is very well suited for the control of very accurate parts. Basically, it is relatively simple and cheap to implement.

The measurement system will therefore be composed of three main elements:

- A target that represents the reference image,

- The object whose surface is to be measured,

- A camera that captures the distorted image reflected by the object to be measured.

Deflectometry has been used for long in the automative industry for qualitative measurement. But there is a major difficulty with deflectometry to make accurate quantitative measurement. It requires a very accurate knowledge of the geometry and position in space of all the elements of the optical system. A well know limitation of deflectometry for shape measurement is a fundamental ambiguity: there is an infinite number of solutions for the shape, depending on the unknown camera-to-object distance. WYSE light patented technology, coaxial deflectometry, overcomes this limitation.

… to coaxial deflectometry (patented)

That’s where innovation lies. Yves SURREL has developed and implemented in the system a calibration method that is very simple and very efficient. It makes it possible to sufficiently characterize the measurement system so as to make usable the images reflected by the object to be measured.

Coaxial deflectometry offers strong advantages over interferometry :

- it is insensitive to vibrations (no need for a optics/damping table, no concrete slab required, can operate even in upper level in a building, or in the shop floor)

- hardware is cheap (maintenance cost is low)

- it is an absolute measurement, it is not differential like interferometry. So it does not require a reference surface. It can measure any type of surface from plane to freeforms without need for costly accessory like CGH (computer generated hologram). Consequently, it is particularly well suited for complex shapes, and the total cost of ownership is much reduced compared to an interferometer,

- it is a full frame measurement, so the need for image stitching is reduced to rare and very specific cases. That makes the full measurement cycle simpler and faster, and definitely more accurate and reliable,

- there is no need for very accurate alignment and centering. Gross positionning at eye sight is ok. That makes measurement fast and simple too,

- …

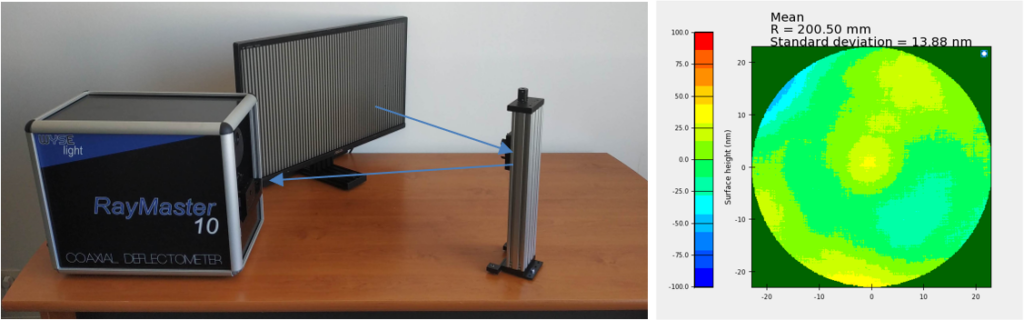

The measuring system sold by Wyse Light:

It consists of a computer screen (see image below) on which the reference images are displayed according to a well-known process. The reflection of the reference images is captured by a camera. The display and camera are connected to a computer that performs the complex calculations necessary to reconstruct the surface. The computer, the camera, and the positioning system of the camera are integrated into a box. The results are displayed on a second screen that presents the user interface (out of sight in the image below).

The innovation developed by Yves Surrel has made it possible to reduce certain variables sufficiently to arrive at a unique and reliable solution whatever the object to be measured. The process has been patented by Wyse Light.

The measurement results obtained are excellent since they reach routinely around 15nm or lambda on 40.

But the development of such an instrument raises the problem of qualifying the measurement results. Indeed, how do you know if the measurement results are good? Do we arrive at the same degree of precision/uncertainty regardless of the forms to be measured? Whatever the materials and their reflective power? whatever the environmental conditions? (ambient light, temperature, hygrometry, air velocity, pollution level…) … We work on reference parts for which we have measurement sets obtained with reference interferometers such as luphoscan and others. The tests improved the understanding of the system’s behavior, and consequently the performance of the instrument. The results are excellent. Do you want to try on your parts? We are ready! Ask for a free trial!